My car, an Audi A4 1.8t, opens the wastegate at 8psi above atmospheric pressure, stock. Since clearly more power is better (and building stuff is entertaining), I needed to make something to adjust the boost setting.

In standard turbocharger systems, there is simply a diaphragm that pops at the set pressure, and allows air to flow into the wastegate, reducing the amount of flow through the turbine, thus lowering the output pressure of the compressor. In the audi, there is a valve called the N75 with a two-conductor cable and 3 hoses connected to it: the turbo compressor tap, the wastegate input, and the airbox (for clean air feed under vacuum). I assumed this was simply a solenoid valve, and energizing it causes it to open. As such, my first code revision simply emulated a manual boost controller: at the set pressure (controlled by potentiometer), energize the valve and open the wastegate.

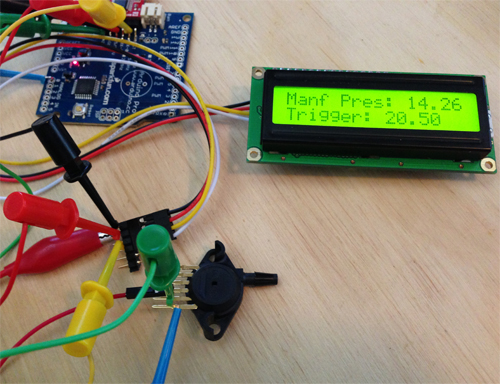

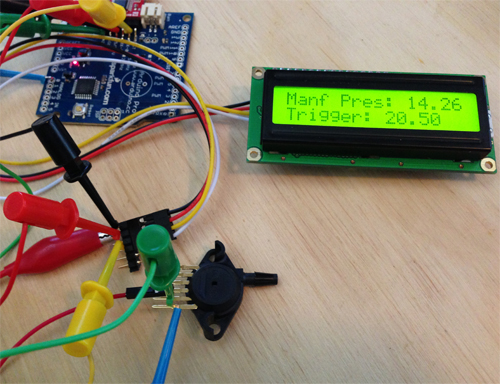

I hacked this all into the car in an evening with an arduino and an N-channel MOSFET (I KNEW that cat5 I ran into the engine compartment would come in handy...) and went for a spin. The results were... unexpected. The car drove just like it did normally and my manifold pressure gauge didn't register anything abnormal, except for one blip where the car unexpectedly made insane power while I was turning a corner. Hmmm.

I plugged the N75 back into the ECU and put my scope on it. Ah! It was being PWM'd!

It turns out the the N75 is actually a spring-controlled valve that begins releasing air at it's set pressure of 8psi over ambient. However, the solenoid coil in it can be pushed in either direction to lower or raise the setpoint. So, my logic was backwards: in order to make more boost, you energize the coil to push against the spring. I adjusted my code to PWM the coil, pushing hardest just above 8psi boost then tapering off to the setpoint for a smooth transition. It works great! The car makes significantly more power running 20psi of boost.

The only issue with that setup was the placement of my pressure transducer: I connected it to the tap from the intake manifold, post-throttle. This means that the turbo can be ramming out 30psi, but if the throttle is closed we still see vacuum. This wouldn't be a huge issue, except that the ECU's manifold pressure sensor is located pre-throttle, and it (a) sets the mixture and (b) cuts the injectors if it sees a dangerous level of boost (about 22psi). Whenever I would sharply accelerate or take my foot off the gas, the resulting spike from the throttle movement would send the pre-throttle pressure over that limit and cause the injectors to cut then surge back - not very great.

I have the system out of the car at the moment to install up front with the new pressure transducer placement just after the turbo. Should be splendid.